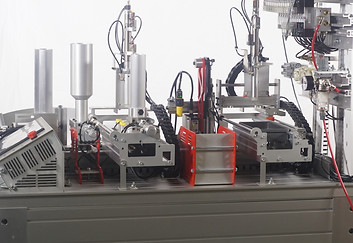

STRUCTURE

MicroProcess-1 is built on a cart with DIN-standard plates supporting all control components.

COMPONENTS

Components manufactured by Lubas Mechatronics Inc.:

-

Cart

-

Overall width: 15.25" (387 mm)

-

Overall length: 39.00" (990 mm)

-

Overall height: 70.00" (178 mm)

-

Height of the plate (worktop): 30.63" (778 mm)

-

Footprint: 39.00''x15.25'' (990 mm x 387 mm)

-

-

Mounting posts

-

Touchscreen console

-

Conveyor

-

Distribution station for round workparts and pots

-

Ball distribution station

-

Lidding station

-

Quality control station with an eject bin

-

Sorting and storage station with a removable six-seat pallet

-

The pallet is removable and once filled, it is removed either manually or by robot. At the customer's option, the robot can be installed on a 5-1/4 "wide plate attached to the current cart on the side. Two shelves can be associated with it, each with empty pallets and filled pallets.

Components chosen by the customer:

-

Set for the treatment of compressed air

-

Electro-pneumatic valve island

-

Two venturi ejector

-

Link blocks

-

Programmable Logic Controller

-

Touchscreen

-

Light tower with four colours

The advantage of reduced footprint

In the laboratory, learning is most effective when students work in teams of two. From one session to the next, they can alternate their roles between manipulation and note taking to writing the report.

So, in a laboratory of twenty students, which is very common, ten systems would be needed. The systems must be as small as possible. Only the MicroProcess-1 meets this requirement.